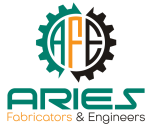

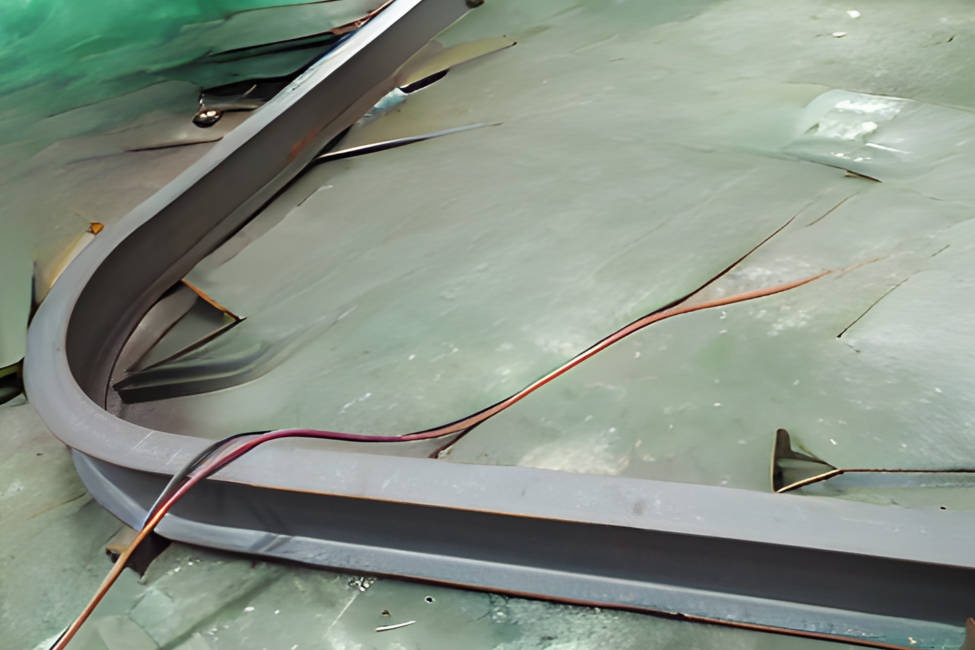

Precision Channel Rolling for Industrial Applications

Application

- Construction

- Tank Fabrication

- Heavy Machinery Erection: industries

Channel Rolling can be defined as one of the most complex metalworking methods. It requires the metal to be bent and a channel to be formed using the respective die. The bending process cannot start until variables like radius, and channel toe are determined. Since Channel Rolling is used for parts that will have to withstand multiple forces, choosing the right service provider is paramount.

At Aries Fabricators & Engineers, we provide precision channel rolling services that meet the demanding needs of industries like construction, tank fabrication, and mechanical erection. Rolling channels to a specified radius—especially for straight sections—requires expertise and advanced machinery to maintain structural integrity without deforming the material.

Machines employed:

Precision Control: Achieving an radius across diverse channel sections is technically complex, requiring high-caliber machinery and skilled operators.

Avoiding Material Deformation: Rolling can lead to uneven stress distribution, which may cause warping or damage to the channels. Controlling these factors while maintaining material strength is crucial.

Why Choose Us?

Expertise: Our team has extensive experience in channel rolling, ensuring minimal material wastage and optimized results.

Custom Solutions: Whether your project demands rolled channels for heavy load-bearing structures or intricate fabrications, we can tailor our services to your exact specifications.

On-Time Delivery: With our streamlined processes, we guarantee timely completion of projects without compromising on quality.

Industries We Serve:

Construction: Structural components, beams, and custom forms.

Tank Fabrication: Rolled channels for cylindrical and conical tank designs.

Heavy Machinery Erection: Support structures and load-bearing elements.

Channel Rolling Specification

Capacity: 36 T x 2000 width maximum

32 T x 2500 D maximum

Higher thickness can be rolled depending upon the width required.

Capacity: 60 T x 2700 width maximum

(Imported Machine) (Hydraulically Operated)

Capacity: 12 T X 2000 width maximum

Minimum Dia 300 can be rolled up to a thickness of 12mm

With the reliable Channel Rolling service from Aries Fabricators & Engineers, you can be assured of guaranteed perfection.

Contact Us Now!

Contact us to discuss your project needs and get expert solutions for your channel rolling requirements. Let us help you stay on track with precision and efficiency!

Aries Fabricators & Engineers

#38-B1, Narayanapura Main Road, 2nd Phase, Peenya Industrial Area, Bangalore – 560058

Our Channel rolling process can be applied metals like:

- Mild steel

- Stainless steel

- Copper

- Aluminum

- Hot/cold rolled variants of the mentioned metals.